Wood laser engraving and cutting can create a wide variety of products. Wood is one of the most common materials used in laser applications due to its durability and natural grain patterns. For practical and aesthetic reasons, customized wood products have a great deal of versatility and are in high demand for many industries such asconstruction, furniture, interior design, and crafts.

In comparison to traditional woodworking methods, wood laser engraving and cutting offer greater convenience, speed, accuracy and efficiency, replacing the need for complex tools like scroll saws, planers, and drills.

Wood as a material boasts strength and hardness as main advantages, but can present challenges in traditional carving and cutting processes. However, lasers can effectively handle various types and hardnesses of wood. Thunder Laser machines can effortlessly cut through even the hardest materials.

Plywood is a multi-layered material made by bonding thin veneers or sheets of wood with adhesive. Composed of an odd number of layers ranging from 3 to 13, plywood ensures uniform wood characteristics and stable shapes by bonding adjacent layers with their grain directions perpendicular to each other.

Compared to solid wood of the same thickness, plywood offers advantages such as high strength, resistance to breakage, and minimal shrinkage or deformation. Among them, birch plywood is known for its durability, waterproof properties, and exceptional strength, making it one of the sturdiest and most stable plywood options for wood laser engraving.

Not all plywood is created equal! Lower quality plywoods includes glues that can melt and will create black soot (instead of brown). To prevent inconsistent results, use a higher quality plywood for a plywood specialized supplier such as Winsor Plywood or similar.

Solid wood is made from complete wood pieces (logs). They are often categorized by the type of wood it used, such as black walnut planks, cherry wood planks, maple, oak, bamboo, and more.

Solid wood is known for its strength, durability, and natural grain patterns. Additionally, most solid woods possess the distinctive aroma of natural wood and exhibit good moisture absorption and breathability. As a result, solid wood planks are considered premium materials for crafting high-end furniture and home renovations.

Medium Density Fiberboard, commonly known as MDF, is a wood product widely used in construction and interior design. It is made from wax, plant fibers mixed with synthetic resins and compressed under high pressure and heat.

MDF is renowed for its exceptional dimensional stability, as it doesn’t warp or expand like natural wood. Its consistent composition allows for precise cutting, drilling, and shaping for wood laser engraving, making it a favorite among craftsmen and woodworkers. Besides, the smooth surface readily accepts paints, veneers, and laminates, enabling endless design possibilities.

Wood laser engraving adds depth, texture, and intricate details, turning simple wooden objects into captivating decor. Different wood species react uniquely to laser etching and burning, creating striking visual depth and contrast.

Artists personalize decor items like wood carvings, wall hangings, signage and picture frames with customized names, logos, and design elements.

Wood laser engraving and cutting allow for customized, elegant details that enhances the aesthetic appeal of furniture pieces. It not only allows creativity in design, but also saves a lot of time compared to hand carving.Laser engraving is used to cut intricate designs in wooden floor panels, fence patterns, wooden blinds, dining table and more.

Thunder Laser Canada will be beginning to offer sales of consumables such as common woods for lasering!

They are convenient for smaller projects and DIY enthusiasts. For example, Home Depot and Lowe’s often have a selection of common wood species. (But, do your research on laser forums first!)

Many online retailers, such as Amazon and Woodworkers Source, sell a wide range of wood products, including exotic and specialty woods. It provides access to a broader selection and may include delivery to your doorstep.

Woodworking shows and expos often feature vendors selling a wide range of wood and related products. It’s an excellent opportunity to see and feel the wood before buying.

They offer wood salvaged from old buildings or repurposed from other sources. This option provides unique, eco-friendly wood choices. You can find them on the ReUse People.

**We’d love to hear what products you are looking for** Please fill out this survey

To receive info when we start selling materials, sign up for our mailing list

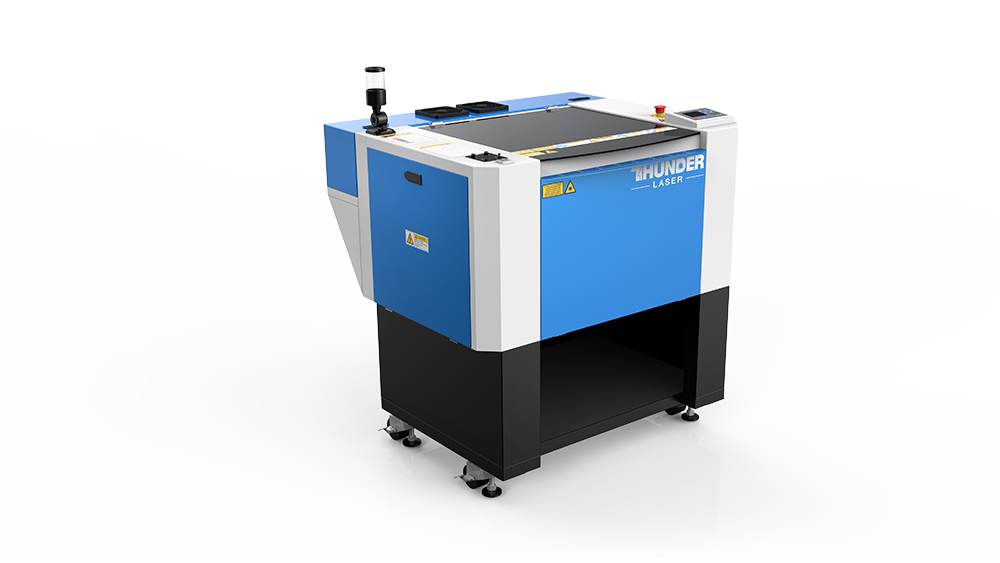

Our Thunder Laser Nova machine delivers unrivaled precision and speed. The stable, robust design of this C02 glass tube laser enables smooth operation and diverse wood laser cutting and the ability to engrave detailed projects. With advanced safety features and minimal maintenance needs, the Nova is a workhorse available in a range range of sizes and tube wattages to match your needs.

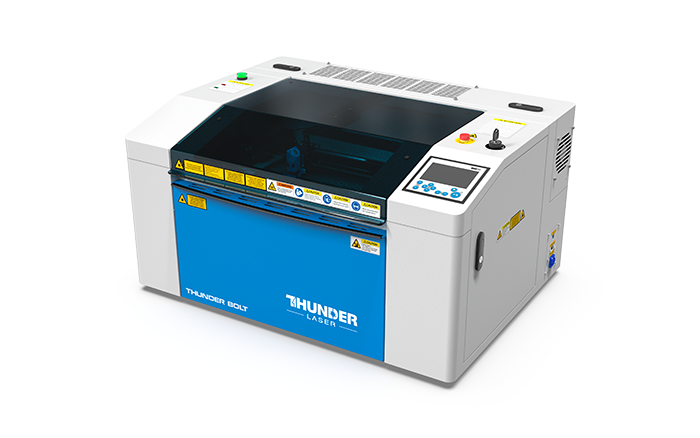

Our Thunder Bolt is an affordable desktop laser machine designed for compact workspaces. Despite its lightweight and portable size, it’s robust C02 Rf tube laser is designed for ultra detailed, intricate engraving work and clean wood cuts. With durability and ease of use, this machine takes highly detailed wood craftsmanship to the next level.

Our Thunder Laser Odin machine is designed for wood laser engraving with lightning-fast precision. As Thunder Bolt’s other sibling, this CO2 RF tube machine has high detail capabilities that are enhanced by special rails that enable captivating 3D effects. Creatives can craft stunning designs by wood laser engraving and cutting with ease.

The results of wood laser engraving and cutting are greatly influenced by the wood material used. Even with the same thickness of the same type of wood, differences in origin, batch, storage conditions, and other factors can lead to variations in hardness, moisture content, and grain patterns, ultimately affecting the outcome.

The table below provides recommended settings for using the Nova laser cutting machine to process wood. You can do some testing first to fit the parameters for a particular use in wood laser engraving and cutting.

Materials | Thickness(mm) | Processing | Speed(mm/s) | Mini Power(%) | Max Power(%) |

Birch Ply | / | Engraving | 500 | 10 | 10 |

3mm | Cutting | 55 | 10 | 90 | |

6mm | 25 | 10 | 90 | ||

10mm | 18 | 10 | 90 | ||

15mm | 3 | 10 | 90 | ||

18mm | 2 | 10 | 90 | ||

Cherry Wood | / | Engraving | 500 | 10 | 20 |

3mm | Cutting | 82 | 10 | 90 | |

8mm | 24 | 10 | 90 | ||

11mm | 16 | 10 | 90 | ||

15mm | 8 | 5 | 90 | ||

20mm | 5 | 10 | 90 | ||

MDF | / | Engraving | 500 | 10 | 20 |

3mm | Cutting | 15 | 10 | 90 | |

10mm | 13 | 10 | 90 | ||

15mm | 5 | 10 | 90 | ||

20mm | x | x | 90 |

*The “×” symbol means this laser machine cannot cut 20mm thick MDF.

During wood laser engraving, the laser energy passes through the material and strikes the honeycomb platform. It is then reflected back onto the backside of the wood by a metal mesh, causing it to char and leaving unwanted and visible marks.

These marks are a result of laser reflection, reducing them can be achieved by minimizing this reflection. Here are several methods to do so:

1.Optimize Processing Parameters. Increase the cutting speed and lower the laser power.

2.Elevate the Wood with a Nail Bed or Similar Tool. Raise the wood above the honeycomb platform for cutting, similar to using a nail bed.

3.Cut with a Knife Blade Beneath the Wood. Cutting with a knife blade beneath the wood, which is less dense than the honeycomb platform. However, it’s essential to cut from the inside out and this method may not be suitable for very small parts.

4.Cover the Backside with Decorative Paper. Place decorative paper on the backside of the wood, allowing it to absorb some of the reflected energy in place of the wood.

5.Enhance Ventilation. Improve the air assist and exhaust system to minimize the smoke and fumes between the wood and the platform.

The principle of wood laser engraving is as follows: laser energy causes the wood surface to char and darken, creating patterns in contrast to the natural wood color. If the wood has a high resin content, deeper engraving marks can be achieved.

Therefore, wood with high resin content, light color, and smooth texture can be used for various intricate vector designs and even photo engravings. Wood with lower resin content, darker color, or distinctive grain patterns may have less pronounced detail in the engravings. For achieving excellent contrast in wood laser engraving, you can choose wood like birch, maple, and cherry wood.

At Thunder Laser, our customers trust the quality of our machines as well as our customer services, which stands out from other laser companies. If you want to see for yourself, check out ratings on Trustpilot.

We became reps for Thunder Laser in Canada, because we are makers ourselves. After using many different types of laser machines over the years, we decided we like Thunder Lasers the best!

Our team is based all over Canada, but our main location and showroom is located at Fuse33 Makerspace in Calgary Alberta. This means, all our members are artists, tradespeople and hobbyists. Our members use our Thunder Laser machines for a wide range of projects. We’ve seen it all!

Let us help you decide which laser machine is best for you according to projects you want to make, space you have available and your budget. We will also help you understand the features and use cases for all of the various add-ons and upgrades available.

Shannon is co-owner of Fuse 33 Makerspace as well as Thunder Laser Canada. He and Maria have built and nurtured the maker community in Calgary (and internationally) for over 10 years, producing countless events and programs such as Calgary MakerFaire, Make Fashion, Artist Residencies and more.

As our lead laser nerd, Shannon works in sales where he nurtures customer relationships and gets people excited about their new laser machines.

Tess is an acro yoga fanatic and a certified laser nerd.

You’ll talk to Tess if you contact sales and she will tell you everything you need to know about lasers. She can help you setup the details of your order and get your new laser shipped right to your door so you can start making right away.

Ben is a super maker, problem solver and tech nerd. Ben uses his analytical super skills to help create Thunder Laser Canada’s systems and processes.

You’ll sometimes find him answering support tickets behind he scenes as well.

Zee Kesler is a maker educator with a love of of hands-on learning. She currently runs a felting company Magic Trout Imaginarium and home decor company Curio Cabin. Previously, she also led the social impact project Makers Making Change where she taught thousands of people how to design, solder, needle felt and make.

You’ll find Zee moderating the Thunder Laser Owner Facebook running our socials, our website and making educational content for teachers!

Reade is a published author, laser nerd and heavy metal fan. Not only does he serve on the Board of Directors for the Toronto Tool Library, but you can also find him hosting demos of our lasers there and replying to your support tickets behind the scenes.

Luna is a seasoned circus performer withLe Cirque de la Nuit,bringing over 10 years of captivating artistry to Thunder Laser Canada. Renowned for her stunning LED creations withnLITEn tech

Luna is a creative force behind captivating videos and social media. You’ll find Luna working behind the scenes to support our logistics. .