Glass engraving, through modern advancements, has greatly enhanced glass processing compared to previous techniques. Glass is an inorganic, non-crystalline solid material. It is often produced by rapidly cooling molten sand, limestone, and soda ash. The cooling process prevents regular crystal growth, giving glass its transparent, glossy and brittle qualities. There are also colored glasses that exhibit color by mixing in certain metal oxides or salts, and tempered glass made by physical or chemical methods.

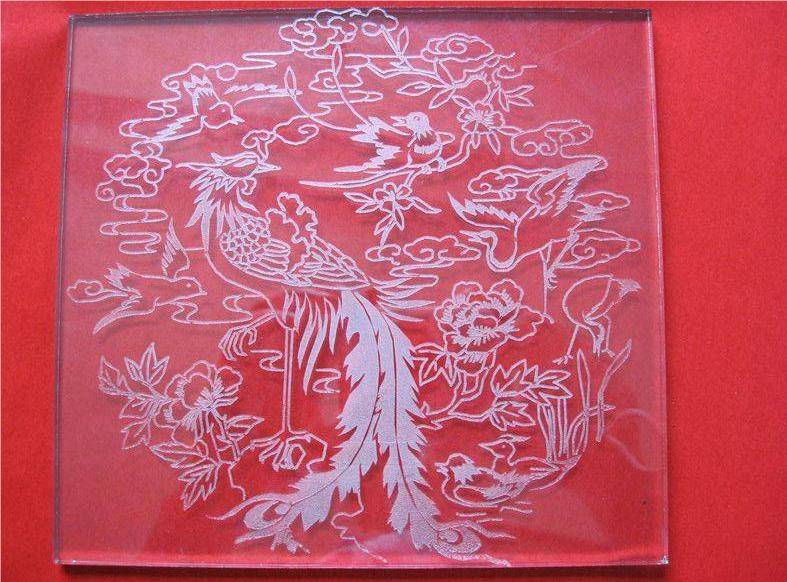

The laser glass engraving allows for intricate designs not possible with other old methods. Additionally, lasers vaporize material cleanly without cracks or chips. This creates smooth edges ideal for glass art, decorations, and transparent components.

Laser glass engraving allows applying logos, stripes, and other ornamental designs to enhance visual styling. As it does not affect the strength, glass engraving decorations can provide unique styling touches and premium branding effects for car owners seeking to personalize their vehicles.

The precision and depth control of laser glass engraving systems allow us to create refined, customized detailing on glassware for gifts, awards, commemorative pieces, and decorative items. Laser glass engraving can produce delicate shading and minute intricacy not achievable by hand engraving.

Glass shops – Specialty stores focused on selling glass for different applications.

Hardware stores – Home improvement retailers like Home Depot carry glass sheets and panels.

Craft stores – Hobby and art supply shops have glass for DIY projects.

Contact glass manufacturers to buy bulk orders directly from the source.

Connect with glass suppliers and distributors who provide materials for reselling.

Work with glass fabricators for customized architectural or specialty glass.

Most CO2 laser machines are capable of glass engraving. Our machines all have excellent capabilities and can perform stable, intricate processing on glass and various other materials. You can select the one most suitable for your needs based on your requirements.

If you want to produce glass engraving items massively, then processing speed and work area will be important selection factors. You may consider our Nova series equipped with larger work areas for higher throughput.

If you intend to create high-precision glass engraving items, then processing accuracy will be the key consideration. Our Odin series, capable of fine and intricate processing, may be a good fit for your needs.

Work Area 600×400 up to 1600×1000mm

Type RF CO2

Power 40w~130w

Z-axis 150mm, 230mm

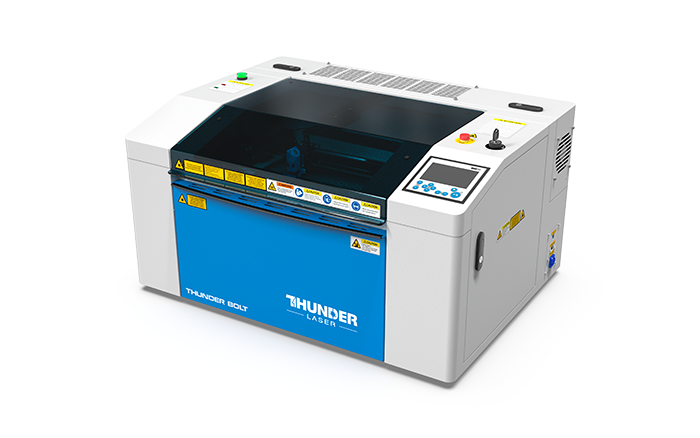

Work Area 508*305 mm

Type RF CO2

Power 30w

Z-axis 110mm

The Thunder Bolt stands out as a small glass workshop with limited space. Despite its portable desktop machine size, it packs powerful CO2 laser tube options plus an innovative air cooling design. This combination of robustness and agile size suits it well for uninterrupted glass engraving operations, as well as processing other diverse materials. Durability enables it to withstand shop conditions while the desktop form factor slots conveniently onto any tabletop without compromising on engraving area or tube strength.

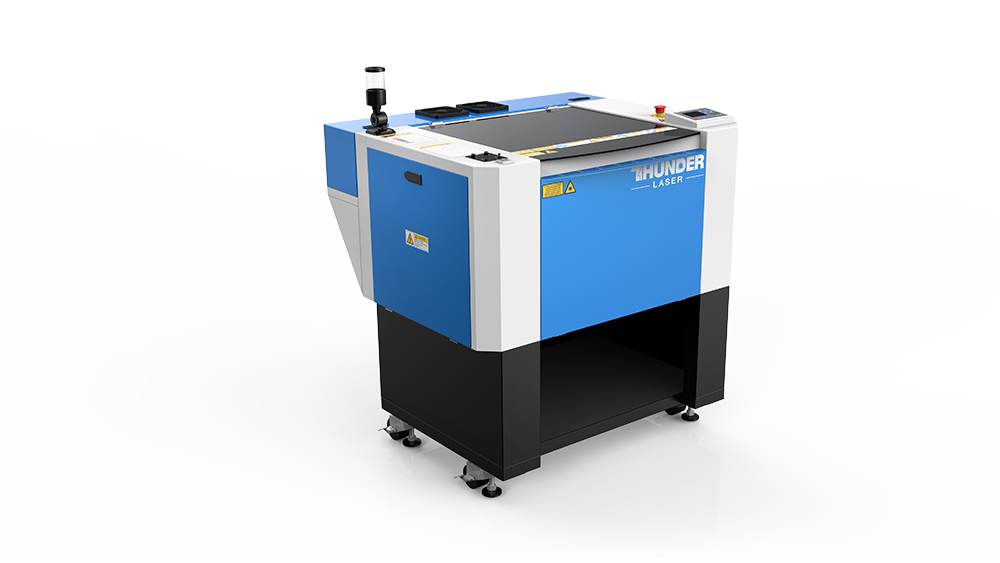

Work Area 559×381 up to 813×508mm

Type RF CO2

Power 30w, 55w

Z-axis 185mm

The Thunder Odin leverages a high-precision RF tube and 3G acceleration to reach swift yet accurate engraving speeds up to 2,000 mm/sec. By combining dynamic performance and superb control, Odin creates smooth gradations and elaborate glass engraving motifs not achievable on less advanced machines. For discerning customers pursuing detailed engraving rather than mass production, Odin’s compact yet capable construction facilitates exceptionally refined glass processing.

Every laser machine has different optimal settings for processing. The table below provides parameters for glass engraving on some of our machines as a reference. We suggest first testing these parameters to check whether they are suitable before proceeding for a particular use.

Machine | Carving effect | Speed(mm/s) | Max Power(%) | Air Pressure Value | DPI | |

NOVA51 (130W) | Engraving | 500 | 10 | 60 | low | 300 |

Nova35 (35W) | 500 | 10 | 80 | 0.1 | 300 | |

Bolt (30W) | 1000 | 50 | 50 | low | 350 |

At Thunder Laser, our customers trust the quality of our machines as well as our customer services, which stands out from other laser companies. If you want to see for yourself, check out ratings on Trustpilot.

We became reps for Thunder Laser in Canada, because we are makers ourselves. After using many different types of laser machines over the years, we decided we like Thunder Lasers the best!

Our team is based all over Canada, but our main location and showroom is located at Fuse33 Makerspace in Calgary Alberta. This means, all our members are artists, tradespeople and hobbyists. Our members use our Thunder Laser machines for a wide range of projects. We’ve seen it all!

Let us help you decide which laser machine is best for you according to projects you want to make, space you have available and your budget. We will also help you understand the features and use cases for all of the various add-ons and upgrades available.