Laser cut acrylic can create wide range of captivating effects. Acrylic is a synthetic polymer material that was first developed in the early 1900s, and became widely used commercially in the 1950s.

The optical clarity of acrylic allows for laser engraved markings to be vividly visible through transparent parts. It also has good thermal stability and low flammability for clean, scorch-free laser cut acrylic. The toughness and scratch resistance provide durability for products. Additionally, it can be fabricated in both colored and clear materials, and takes painting and printing inks well for further customization.

Acrylic has become the go-to material for creating detailed and personalized laser-cut products across many applications.

Thunder Laser Canada will be beginning to offer sales of consumables such as acrylics for lasering!

**We’d love to hear what products you are looking for** Please fill out this survey

To receive info when we start selling materials, sign up for our mailing list

You can purchase various acrylic materials from online retailers such as eBay, Home Depot , and Amazon. You can find clear and colored acrylic sheets, acrylic rods, and acrylic craft supplies.

When working with acrylic material, here are some tips for optimized laser cut acrylic results.

Use a laser or flame polishing technique to smooth and remove roughness from cut acrylic edges. Avoid mechanical sanding, which can induce microfractures and cracks.

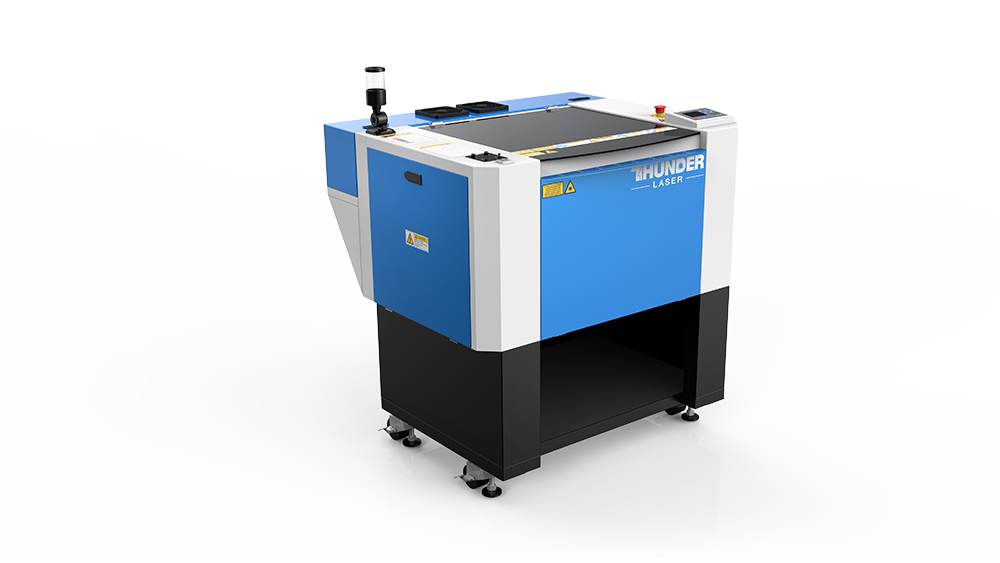

Our Thunder Laser Nova machine delivers unrivaled precision and speed. The stable, robust design of this C02 glass tube laser enables smooth operation and diverse acrylic laser cutting and the ability to engrave detailed projects. With advanced safety features and minimal maintenance needs, the Nova is a workhorse available in a range range of sizes and tube wattages to match your needs.

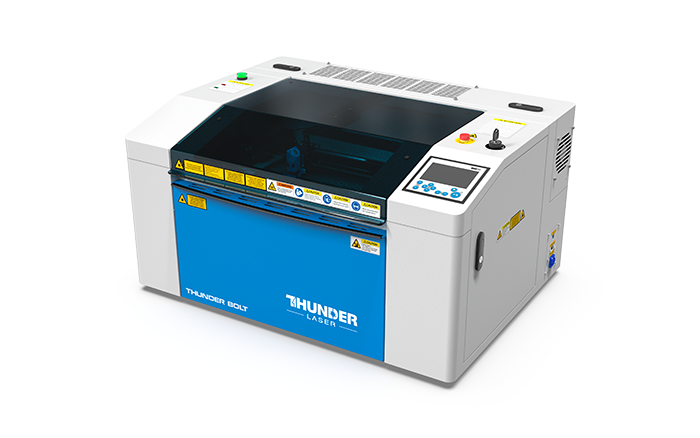

Our Thunder Bolt is an affordable desktop laser machine designed for compact workspaces. Despite its lightweight and portable size, it’s robust C02 Rf tube laser is designed for ultra detailed, intricate engraving work and clean wood cuts. With durability and ease of use, this machine takes highly detailed acrylic project to the next level.

Our Thunder Laser Odin machine is designed for wood laser engraving with lightning-fast precision. As Thunder Bolt’s other sibling, this CO2 RF tube machine has high detail capabilities that are enhanced by special rails that enable captivating 3D effects. Creatives can craft stunning designs by laser engraving and cutting acrylic with ease.

The table below provides recommended laser settings for using the Nova laser cutting machine to process acrylic. You can do some testing first to fit the laser-cut acrylic parameters for a particular use.

Material | Thickness | Processing | Speed(mm/s) | Mini Power(%) | Max Power(%) | Air Pressure Value | DPI |

Acrylic |

| Engraving | 500 | 10 | 10 | low | 300 |

3mm | Cutting | 60 | 10 | 90 | high | 2” | |

5mm | 30 | 10 | 90 | high | 2” | ||

10mm | 7 | 10 | 90 | high | 2” | ||

15mm | 3 | 10 | 90 | high | 4” | ||

20mm | 2 | 10 | 90 | high | 4” |

Here is a video engraving acrylic with our laser machine. Check it out to see the effects it can achieve!

During the process of laser cut acrylic, the focused beam can reflect off the honeycomb bed and damage the acrylic backside, leaving unwanted marks. To minimize these backside markings, consider the following techniques:

1、For small projects, you can place damp paper towels underneath the acylic. It can dampen the reflected energy and safeguard the acrylic surface.

2、For larger projects, lift the acrylic off the bed using nail boards or other fixturing. This reduces reflected energy by dissipating it before reaching the acrylic.

3、Consider using knife bars instead of a honeycomb bed when processing acrylic. The more open structure reflects less laser back upwards. Cut for an inside-out approach and avoid working with very small parts.

4、Optimize processing parameters to higher speeds and lower power so less energy reflects back per unit time.

1、Adjust Blowing and Speed

To reduce striations and rough edges on acrylic, use weak blowing while decreasing laser cutting and engraving speeds.

2、Balance Power and Speed:

Excessive power can lead to acrylic melting, while slower speeds can hinder laser processing efficiency. You can experiment with settings to find the optimal configuration. For 10mm acrylic, use 80-90% power and 5% speed; thinner sheets require lower power and faster speeds.

3、Multiple Passes:

Choose multiple passes at lower power over one pass at maximum power. Gradually refine the edge without excessive heat buildup. For 5mm acrylic, you may try 3-4 passes at 50% power for smooth edges.

1、Adjust the air assist to lower the temperature at the cut lines, avoiding ignition from excessive heat.

2、Place wet paper towels which can use the moisture and evaporating water vapor to reduce the temperature during laser processing. The wet kitchen towels will also work.

At Thunder Laser, our customers trust the quality of our machines as well as our customer services, which stands out from other laser companies. If you want to see for yourself, check out ratings on Trustpilot.

Shannon is co-owner of Fuse 33 Makerspace as well as Thunder Laser Canada. He and Maria have built and nurtured the maker community in Calgary (and internationally) for over 10 years, producing countless events and programs such as Calgary MakerFaire, Make Fashion, Artist Residencies and more.

As our lead laser nerd, Shannon works in sales where he nurtures customer relationships and gets people excited about their new laser machines.

Tess is an acro yoga fanatic and a certified laser nerd.

You’ll talk to Tess if you contact sales and she will tell you everything you need to know about lasers. She can help you setup the details of your order and get your new laser shipped right to your door so you can start making right away.

Ben is a super maker, problem solver and tech nerd. Ben uses his analytical super skills to help create Thunder Laser Canada’s systems and processes.

You’ll sometimes find him answering support tickets behind he scenes as well.

Zee Kesler is a maker educator with a love of of hands-on learning. She currently runs a felting company Magic Trout Imaginarium and home decor company Curio Cabin. Previously, she also led the social impact project Makers Making Change where she taught thousands of people how to design, solder, needle felt and make.

You’ll find Zee moderating the Thunder Laser Owner Facebook running our socials, our website and making educational content for teachers!

Reade is a published author, laser nerd and heavy metal fan. Not only does he serve on the Board of Directors for the Toronto Tool Library, but you can also find him hosting demos of our lasers there and replying to your support tickets behind the scenes.

Luna is a seasoned circus performer withLe Cirque de la Nuit,bringing over 10 years of captivating artistry to Thunder Laser Canada. Renowned for her stunning LED creations withnLITEn tech

Luna is a creative force behind captivating videos and social media. You’ll find Luna working behind the scenes to support our logistics. .