Leather laser engraving and cutting is an efficient way to manufacture, stylize and customize your leather products. Leather is a durable, flexible material made from animal hides that develops a unique patina over time. A major selling point of leather, is its natural breathability which makes it ideal for apparel and accessories. Additionally, the strength makes for a long lifespan which is ideal for daily items like bags and furniture. Another aspect that makes leather a great making material is its malleability; it can easily mold to the shape of the body.

Today, leather is used extensively in accessories, sporting goods, furniture, and many other products. By using laser engraving techniques, crafters can add intricate personalized patterns to leather goods.

The leather industry will continue evolving by adopting new technologies. Sustainability will be a priority, with greener processes to reduce environmental impact. Now, leather manufacturers are beginning to incorporate more efficient customization techniques like laser engraving and 3D printing. Plant-based and lab-grown leathers will also increase in popularity. Despite the popularity of non-animal alternatives, leather’s natural appeal will persist.

The adoption of new techniques and technologies is likely to drive progress in leatherworking. It’s evident that laser engraving leather is becoming a popular avenue explored by artisans as well as large companies.

Here are some tips on where and how to buy leather materials:

Leather Selection Tips

Laser technology, including leather laser engraving and cutting, is gaining popularity in leather goods for its ability to create intricate designs with minimal waste.

Common leather laser engraving and cutting goods include:

Leather jacket – Allowing more intricate shaping and detailing for stylish leather jackets.

Leather pants – Precise laser cuts giving a close, tailored fit.

Leather skirt – Easily create flattering shaping and custom designs and patterns in leather skirts.

Leather boots – Laser perforations add breathability to leather boots.

Leather recliner – Intricate laser cutting shapes ergonomic leather recliners.

Leather couch/sofa – Easily customize panels and designs on leather couches.

Leather chair – Creating complex laser cut leather chair designs.

Leather backpacks – Creating durable yet stylish leather backpacks.

Leather purse/wallet – Accurate leather laser engraving and cutting are employed in crafting items like purses and wallets.

Leather armour – Shaping lightweight, flexible laser engraved and cut leather armour.

Leather dog collar – Producing customized and durable leather collars.

saddle back leather – Intricately designed saddle leather.

Faux leather – Laser processing mimics the qualities of real leather, including PVC and PU leather.

Vegan leather – Offering animal-free processing of vegan leather.

RF CO2

30w,55w

110×110 up to 200×200mm

20w,50w,20w MOPA

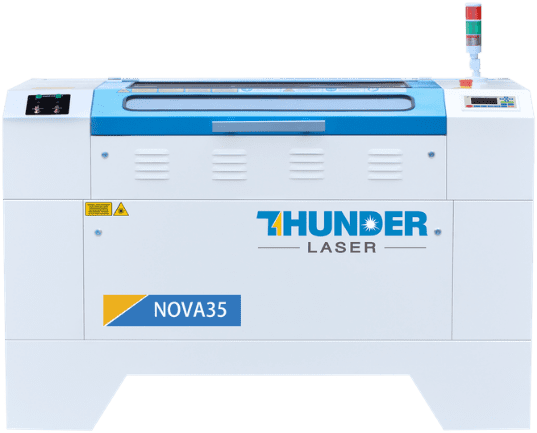

With the right laser machine and techniques, leather can be cut, etched, and marked to perfection. Learn more about Thunder Laser systems at www.thunderlaser.ca.

Material | Thickness (mm) | Processing | Speed (mm/s) | Min Power (%) | Max Power (%) | Air Pressure Value | DPI |

leather | / | Engraving | 500 | 10 | 20 | low | 300 |

1.50mm | Cutting | 135 | 10 | 90 | high | 2″ | |

3.00mm | Cutting | 100 | 10 | 90 | high | 2″ |

If leather deforms during laser cutting, the power is likely too high. Try lowering laser power.

Faux leathers often have a fabric backing, making their structure more stable. Wet rags or cotton pads can easily wipe away residue.

Laser engraving faux leather can create light color variations when defocused.

At Thunder Laser, our customers trust the quality of our machines as well as our customer services, which stands out from other laser companies.. If you want to see for yourself, check out our ratings on Trustpilot .

We became reps for Thunder Laser in Canada, because we are makers ourselves. After using many different types of laser machines over the years, we decided we like Thunder Lasers the best!

Our team is based all over Canada, but our main location and showroom is located at Fuse33 Makerspace in Calgary Alberta. This means, all our members are artists, tradespeople and hobbyists. Our members use our Thunder Laser machines for a wide range of projects. We’ve seen it all!

Let us help you decide which laser machine is best for you according to projects you want to make, space you have available and your budget. We will also help you understand the features and use cases for all of the various add-ons and upgrades available.