A laser is a fantastic fabric cutting machine which can make improvements to many types of fabric products. Fabric is a material made of fibers twisted or bonded together. It is lightweight, porous, flexible and durable. It can be woven, knitted or non-woven into various textures and patterns.

Fabric is an ideal material for laser processing. Its lightweight structure means there is less drag on the laser, enabling faster movement and processing. Besides, laser cutting fabric produces clean, accurate edges without excessive scorching or melting.

Fabrics like cotton, polyester and nylon are especially suitable with their ability to vaporize cleanly when exposed to laser. Compared to manual cutting and stitching, laser fabric processing is more efficient, consistent and scalable. Laser processing by fabric cutting machine gives infinite design options and customization on fabric for fashion, upholstery, banners and more.

Large exhibitions like Outdoor Retailer allow discovering new fabrics and meeting suppliers from around the world. But the minimum order is often higher.

Brick and mortar stores like Joann Fabric provide opportunity to feel fabrics in person with the guidance from knowledgeable staff. It often offers customization services.

Laser cutting is ideal for processing various fabrics with its ability to cut intricate designs and patterns quickly, accurately and without contact. The concentrated heat of the laser cleanly severs the textile fibers without excessive scorching or fraying. With programmable digital control, laser cutters can repeatedly create complex custom designs.

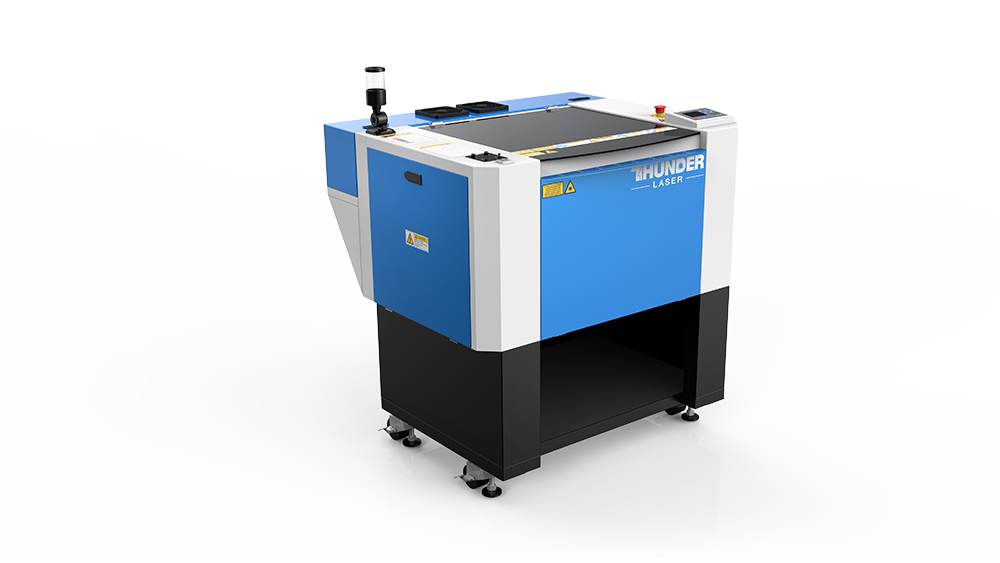

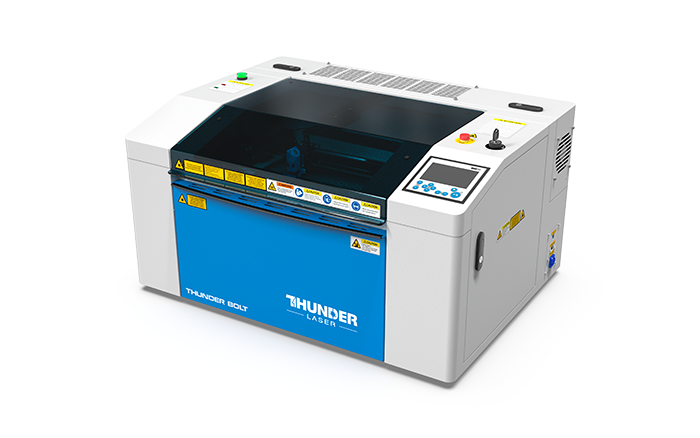

Whether making unique fashion pieces, home items or crafts, you’ll need an excellent fabric cutting machine. The Thunder Laser machine provides the power, precision and reliability required to take your fabric projects to the next level.

Work Area 559×381 up to 813×508mm

Type RF CO2

Power 30w, 55w

Z-axis 185mm

Work Area 508*305 mm

Type RF CO2

Power 30w

Z-axis 110mm

Work Area 600×400 up to 1600×1000mm

Type RF CO2

Power 40w~130w

Z-axis 150mm, 230mm

With its spacious work area, the Thunder Nova enables laser cutting of large swaths of fabrics. Available in multiple sizes, Nova machines feature an adjustable bed to accommodate different material thicknesses. It also delivers excellent engraving resolution on fabrics due to its hybrid servo motors. Additionally, the user-friendly designs make Nova an excellent fabric cutting machine for processing high volumes of fabrics or oversized projects with power and quality.

The results of fabric engraving are greatly influenced by the fabric material used. The table below provides recommended settings for using the NOVA51-130W laser machine to process fabric. You can do some testing first to fit the parameters for a particular use by fabric cutting machine.

|

Materials |

Thickness(mm) |

Processing |

Speed(mm/s) |

Mini Power(%) |

Max Power(%) |

|

Denim |

/ |

Engraving |

500 |

5 |

5 |

|

1mm |

Cutting |

300 |

10 |

90 |

|

|

Cotton Fabric |

/ |

Engraving |

500 |

10 |

10 |

|

1mm |

Cutting |

300 |

10 |

90 |

|

|

3mm |

300 |

10 |

90 |

The moisture minimizes potential damage to fibers during lasing that causes instability. As a result, you can increase fabric humidity.

Defocus the laser or adjust grayscale patterns of laser fabric cutting machine to maintain fabric stability. You can also use finer techniques directly on the material itself to keep the textile stable.

Keep dry: Store fabrics in a well-ventilated area at room temperature, away from direct sunlight, heat sources or moisture. Use an appropriate amount of moth-proofing agents.

Avoid light exposure: Sunlight can cause dyes to fade. Ideal storage is in a dark place or bagged to prevent light exposure.

Control temperature: High temperatures may cause fabrics to shrink while low temperatures can produce stiffness. The ideal range is 15-25°C.

Prevent mildew: Use anti-mildew agents as needed. In hot and humid seasons, periodically air out the fabrics to prevent mold growth.

Fold neatly: Avoid creases by placing sheets of soft cloth or paper between folded fabrics.

At Thunder Laser, our customers trust the quality of our machines as well as our customer services, which stands out from other laser companies. If you want to see for yourself, check out ratings on Trustpilot.

We became reps for Thunder Laser in Canada, because we are makers ourselves. After using many different types of laser machines over the years, we decided we like Thunder Lasers the best!

Our team is based all over Canada, but our main location and showroom is located at Fuse33 Makerspace in Calgary Alberta. This means, all our members are artists, tradespeople and hobbyists. Our members use our Thunder Laser machines for a wide range of projects. We’ve seen it all!

Let us help you decide which laser machine is best for you according to projects you want to make, space you have available and your budget. We will also help you understand the features and use cases for all of the various add-ons and upgrades available.